Plasma cutting is a significantly important method of cutting any conductive products such as non-alloy steel, stainless steel, iron, and aluminium with minimum effort and expense. The basis of the working logic is to convert an ionized gas into plasma form and create an electrical channel towards the area to be cut. The plasma cutting process is performed by plasma cutting machines developed with the latest technology.

The gas type and pressure to be used during the cutting process inside the machine may vary depending on the material type and thickness to be cut. In addition, some of the compressed gasses such as oxygen and air are ionized by an electric arc. The ionized gas enables the desired cutting process to take place on the line formed between the cutting edge of the plasma machine and the material to be treated.

The most important criterion needed for plasma cutting is known as compressed gas. In addition to using different gases for this process, the most common plasma gas is compressed air. As it is available in many workshops and manufacturing shops, compressed air is very easy to supply. It can be used as an alternative to flammable and combustible due to its easy supply and accessibility.

Considering both in terms of health and the environment, performing cuttings with compressed gas is a much healthier and environmentally friendly process. As Durmazlar, we are going to discuss how plasma cutting works and the differences between plasma and laser cutting.

How Does Plasma Cutting Work?

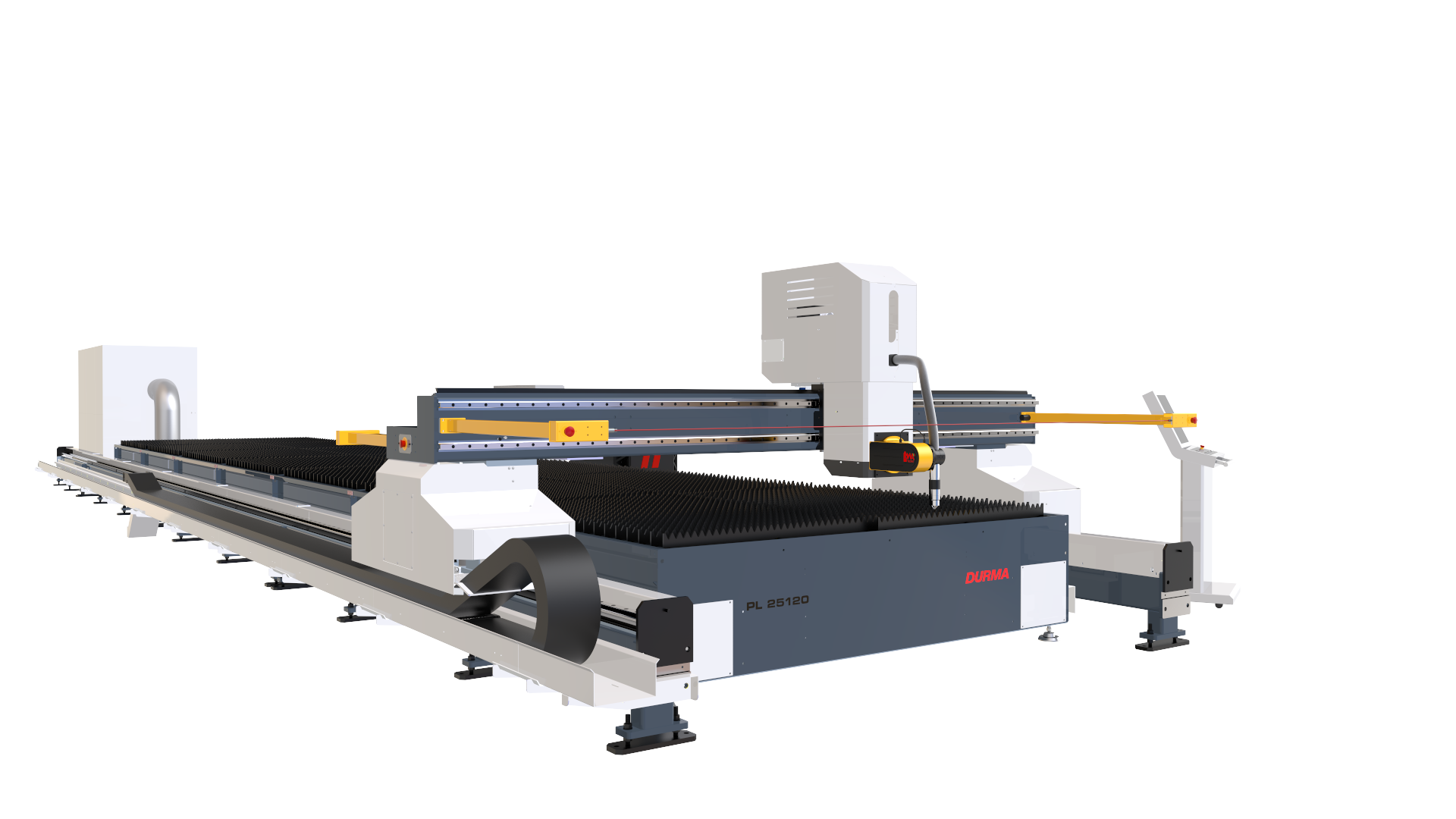

During plasma cutting, hot and accelerated plasma is applied to the surface of the material with high electrical conductivity to be cut. Thanks to this cutting method, conductive materials such as aluminium, steel, sheet metal, and copper can be cut very fast and perfectly. Plasma-cutting machines are preferred by large industrial companies and many other areas with their high-speed precision cutting and low operating costs.

The main criterion of plasma cutting is that it creates an electrical channel through the material to be cut by a superheated and electrically ionized gas. This electrical circuit is grounded by the grounding busbar, thus ensuring the operation of the system. In accordance with the material to be cut by the operation of this system, compressed gasses such as oxygen and air are used. The electric arc is shaped between the hole (nozzle) in which the gas comes out and the material. An electric arc ionizes some of the gas and enables the creation of an electrical channel between the plasma and the material.

By using this electrical channel, electrons travel to the material through a cutting torch and create the heat needed to melt the material. During this process, high-velocity plasma and compressed gas spray the molten metals, preventing the formation of any roughness on the surface.

You can perform cuts on both fine and thick materials using plasma cutting. Steel sheets of 38 mm thickness can be cut using manual plasma cutting machines. Moreover, cuttings up to 150 mm in thickness can be performed with plasma cutting machines.

What Are The Advantages Of Plasma Cutting?

One of the most efficient ways to obtain products in desired sizes and shapes from metals such as steel, iron, and aluminium is plasma cutting. There are many advantages of using this method in manufacturing shops, workshops, and repair shops. One of these advantages is productivity.

It is possible to perform more cuts in a shorter time using this method. Cutting more products in a shorter time means producing more products in a shorter time for a manufacturing shop. This also means more production with less human power. Therefore a manufacturing shop or workshop can produce more with fewer workmanship costs.

Another productivity contribution of plasma cutting is that there is no need for a pre-annealing process before cutting. This means that the material to be cut is not exposed to any heating process before cutting. Heating and cutting the metal to be cut at a certain temperature increases both the time and effort spent on the work. Loss of material due to a possible error that may occur in the heating process can also be prevented.

As it is in the cutting process, plasma cutting offers great convenience after the process. The cutting torches of plasma cutting machines are performing much more precise and smoother works with the technology that has developed recently. Thus, no slag that needs to be cleaned after cutting is created. Since it performs the best cut with the least force on the material to be cut, post-cutting correction is not needed as there will be no adverse conditions such as warping, bending, or distortion on the surface post-cutting.

This cutting method offers advantages regarding health and the environment. Apart from these, the fact that the gas used in the machines is non-hazardous is also a great advantage in terms of occupational safety. The non-explosive and non-flammable gas used prevents an explosion or fire that may occur in the workplace.

What Is the Importance of Plasma Cutting?

Plasma cutting is preferred for cutting many metals thanks to its advantages. Almost all of these advantages also offer advantages for cutting stainless steel. In addition to these advantages, plasma cutting also prevents major workmanship errors in steel cutting.

Another importance of plasma cutting is that it produces accurate results after cutting. Since the measurements determined before the cutting are reflected in the work in the same way, there is no mistake or errors.

In this article, as Durmazlar, we will answer in detail about the advantages of plasma cutting and plasma cutting machines. By using Durmazlar machines, you can overcome all difficulties. We mainly aim to combine business processes by producing durable, flexible, and innovative machines. We aim for perfection in all our machines and attach importance to our communication with our customers in order to produce flawless machines. Please visit our website and contact us if you need further information about our products.