Smart factory is a manufacturing model where digital technologies are heavily used in production processes. In this model, all devices, machines, sensors, and systems used in the production process are interconnected and create a data network. As a result, all data in the production process can be tracked, analyzed, and managed in real-time, which increases efficiency, minimizes errors, and reduces costs.

Smart factories are advanced technology production facilities that differ from automated machines aiming to minimize human labor and needs as they integrate artificial intelligence systems into the process. Instead of human labor used in production processes, fully automated systems are used, and any obstacles that may arise in the process are solved with artificial intelligence to maintain the system’s existence.

The competitive society of today has come to better understand the importance of such systems during the pandemic. Artificial intelligence, which has started to offer services in many fields using future technologies, has also begun to be used in many sectors. The integration of artificial intelligence and full automation into factory processes has given rise to the concept of smart factories.

The Smart Factory system emerges as a good method for achieving complete harmony among the manufacturer, supply chain, and customers, and for obtaining maximum benefit. Smart systems can adjust production lines according to customer demands and send the necessary products to the supply chain in real-time. This way, the dependence on labor will be reduced, and disruptions in production, especially during pandemic periods, will be kept to a minimum.

Transition to Smart Factories with Industry 4.0

Industry 4.0 can be defined as the integration of the current control and planning system applied on complex production tools in factories with today’s technologies and made compatible with software. Industry 4.0 is important in today’s world due to its dynamic nature. It is a system that includes the design of a fast, serial, and efficient production system and its implementation in the field, in a world where competition and production stand out.

Smart Factory is developed as a structure that is compatible with Industry 4.0 as a system. It appears as a technological reflection of the fourth industrial revolution in factories. The integration of computer systems with automation systems has been taken to an even higher level today, and artificial intelligence has also entered the game. The control of production lines is carried out in a fully automated system, and the management is carried out by artificial intelligence at certain points, which means that the system can develop further.management is carried out by artificial intelligence at certain points, which means that the system can be further developed.

With the integration of artificial intelligence into the system, self-monitoring of the production lines, instant intervention in case of malfunctions, automatic activation of different systems, and support for improvement efforts of the system have become prominent features. The system minimizes production disruptions caused by human errors in the harmony between humans and machines.

The Smart Factory is the key to achieving maximum efficiency in the production and logistics channels, while also facilitating the production of the most accurate and appropriate products at the right time according to the demands of society or consumers. With the transition to factories that employ smart production with Industry 4.0, it is possible to have a system that can:

- Ability to extract data from the sales system

- Analyze incoming orders , automatically plan production based on warehouse and inventory status

- It is a system that can transfer information to the logistics system,

- Determine the destinations where products need to be shipped, and identify the required delivery timeframes for timely delivery.

Smart Machines Used in Production from Past to Present

The Smart Factory is the latest point reached in the manufacturing industry and is considered the first, second, third, and fourth industrial revolutions of the past. It is true that the systems used in manufacturing and production processes have undergone evolution from the past to the present. In the First Industrial Revolution, water and steam power were used for manufacturing and production processes, while the discovery of electricity in the Second Industrial Revolution led to the emergence of systematic production processes.

The third industrial era enabled the transition to automation systems by the use of information technologies, while the fourth industrial era opened the door to the era of smart factories.

The Future of Technology

The future impact of technology and the changes it will bring to human life is one of the most intriguing topics. Today’s technology aims to integrate the entire ecosystem using automation systems and artificial intelligence. The innovations brought by the information age and digital transformation and development are important agenda items of today. The increasing importance of artificial intelligence and robot technology indicates that the future will take a different direction.

Smart factories are managed through collaboration achieved by full automation and the use of artificial intelligence. This creates a new trend by designing a system that is compatible with the entire ecosystem. However, it is predicted that technology will reach future generations in a much more advanced way. Especially with the use of artificial intelligence in robots, it is already possible to perform many tasks through robots.

With the advancement of technology, robots can completely automate factory management and production processes, thus reducing the workload of humans. The widespread use of unmanned vehicles can make travel more efficient and comfortable. Moreover, as a result of these developments, shopping data can be collected to make the production process smarter and more organized.

The Smart Factory will become capable of making decisions for production planning, manufacturing stages, and even choosing logistics channels. Human beings will only have the task of controlling this entire system.

Development of Smart Factories in the Machinery Industry

The development of smart factories in the machinery industry has gained momentum in recent years, and it is expected that this trend will continue in the future. Smart factories are designed to make production processes more efficient, fast, and flexible, and to reduce production costs and improve product quality through the use of digital technologies.

In these smart factories, technologies such as the Artificial Intelligence (AI), cloud computing, and big data are used to automatically control machines and equipment, detect maintenance and repair needs in advance, and increase efficiency in the production process.

With this development, manufacturers will have the capacity to produce higher quality products and make their production processes more flexible. Moreover, through smart factories, manufacturers will reduce production costs and increase their competitiveness.

As a result, the development of smart factories in the machinery sector is considered an important trend for the future of the industry and is expected to continue.

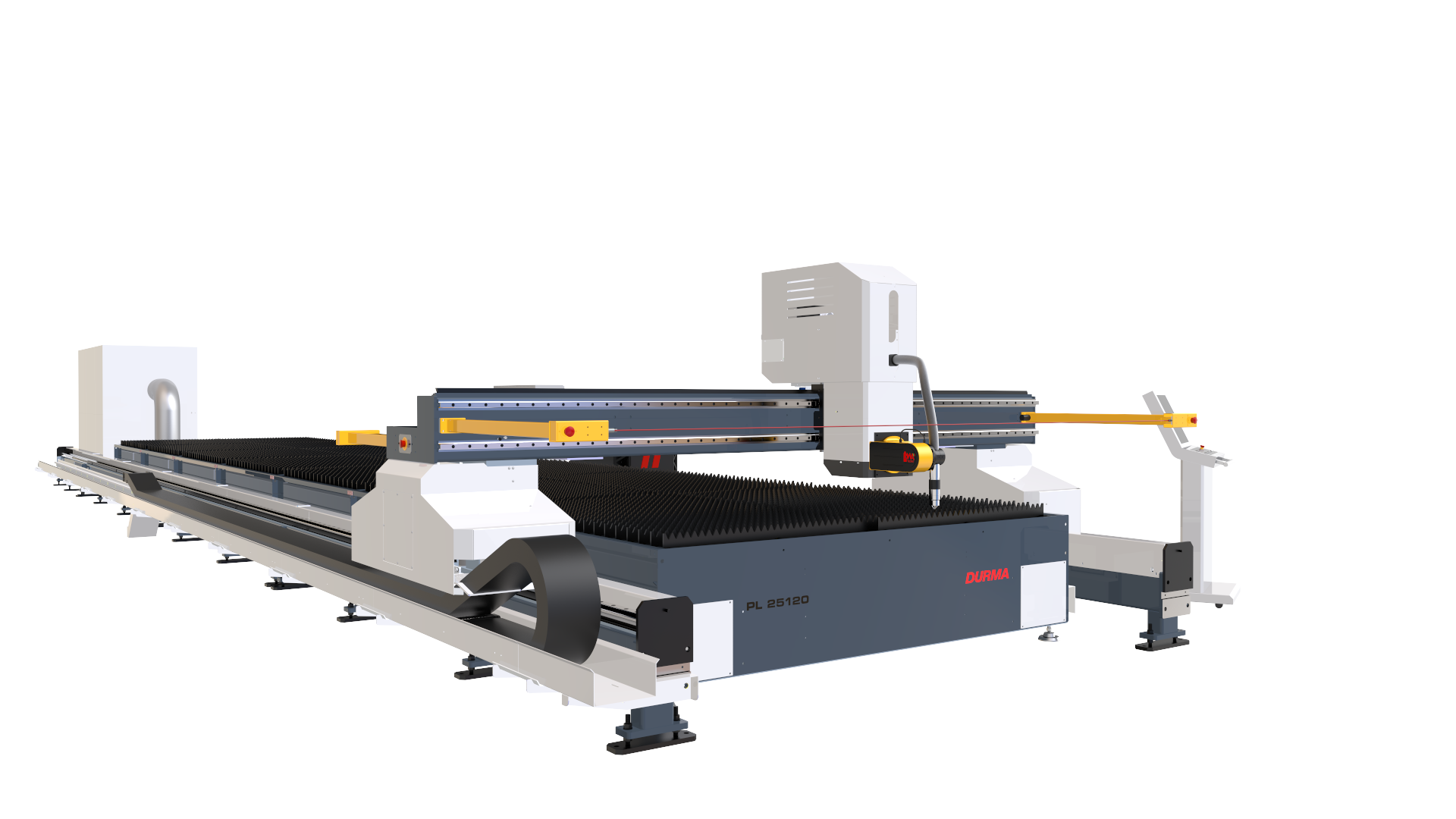

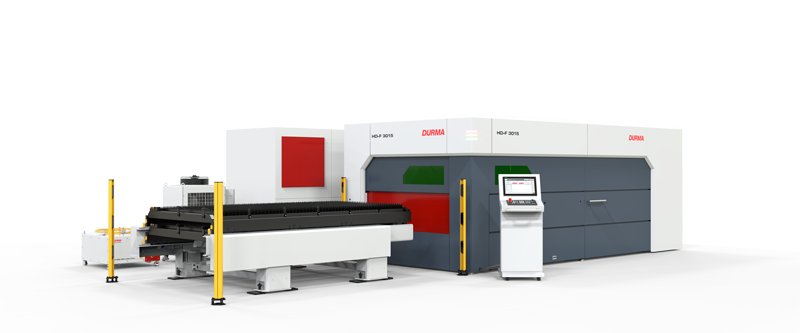

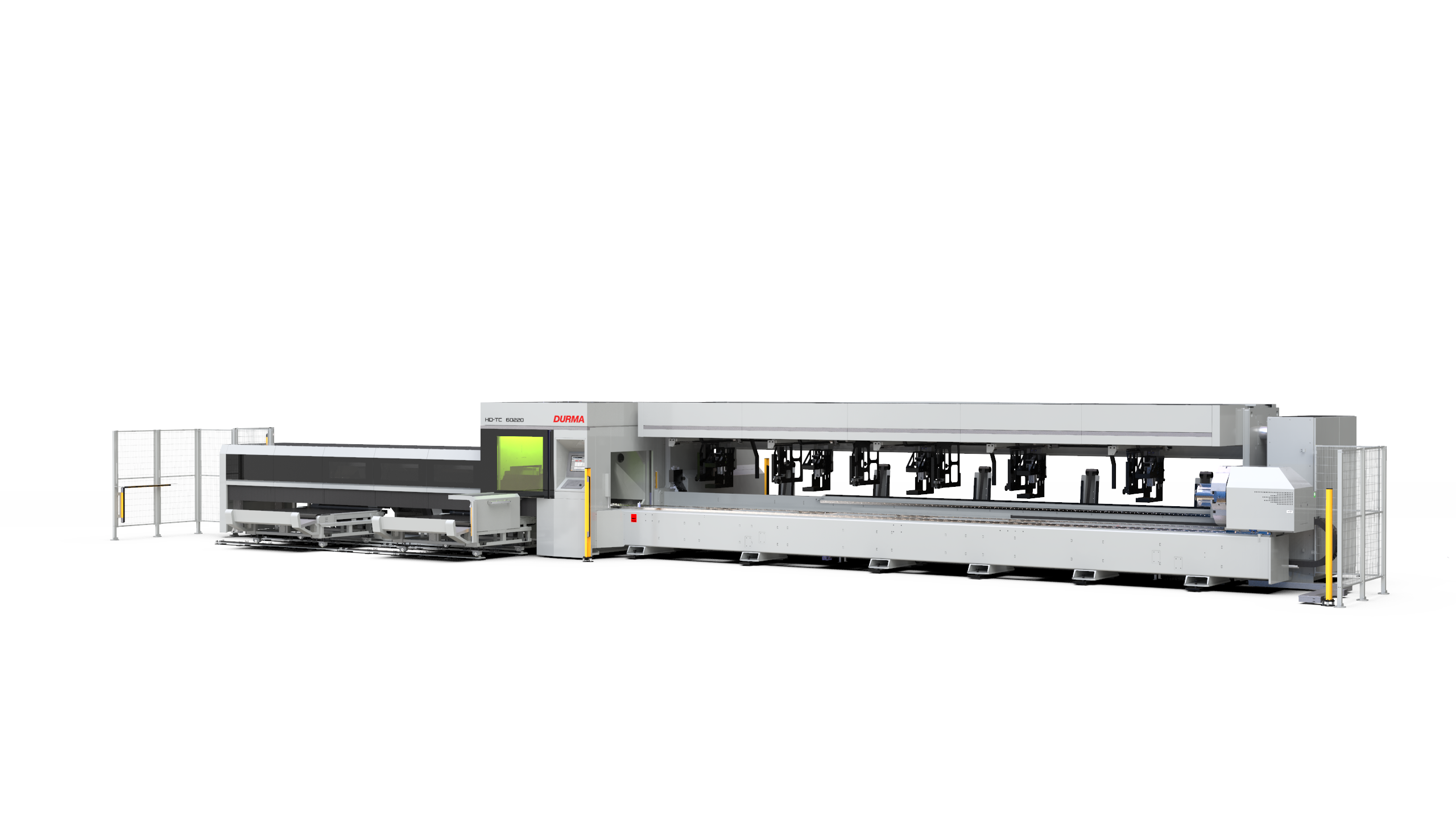

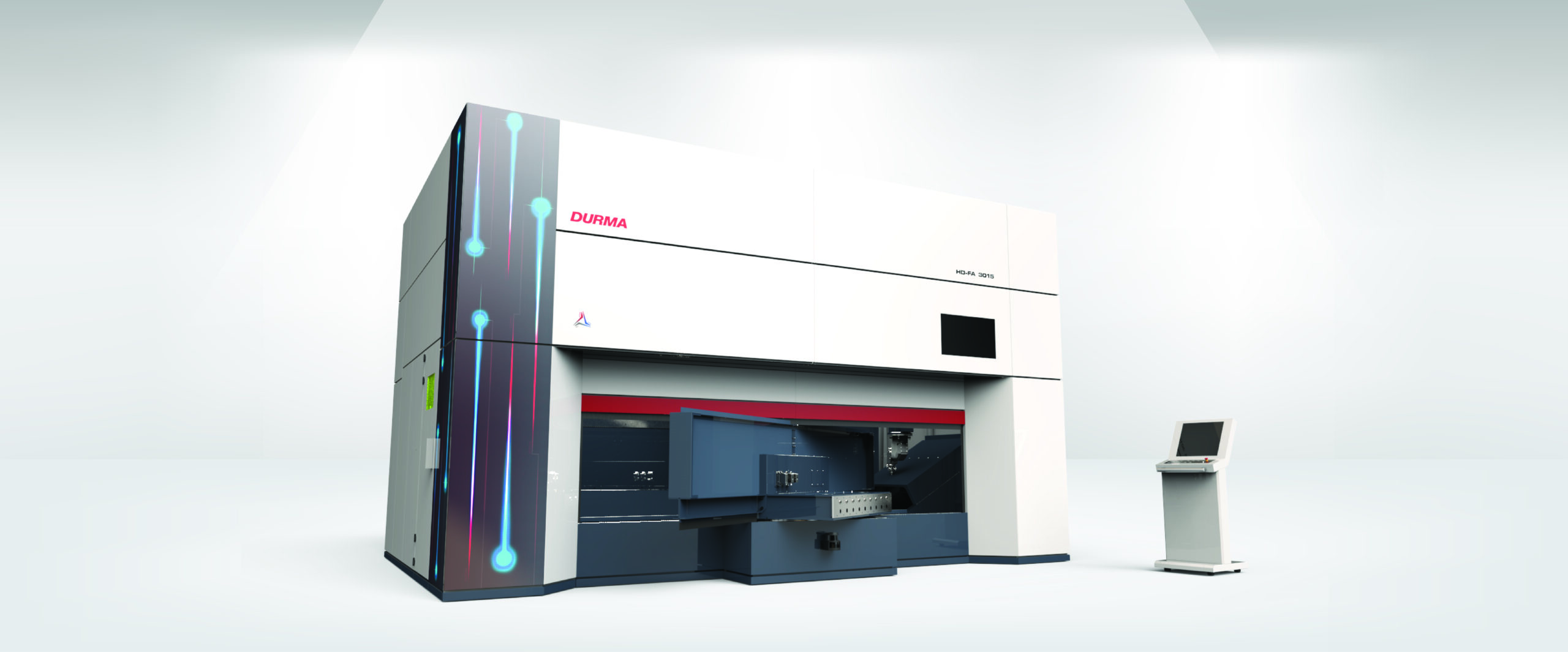

Durmazlar Makina is a leading company in the production of transportation vehicles such as buses, trams, metros, and high-speed trains. Like other manufacturers, Durmazlar Makina is investing in the development of smart factories and aims to create a more efficient, fast, and high-quality production process. Therefore, it is supporting its investments with smart factory production processes and digital technologies.

Digital Digital technologies such as robotic systems, artificial intelligence (AI), and big data are among the technologies used in Durmazlar Makina’s smart factory. With the help of these technologies, the production process has been automated, minimizing errors and increasing production efficiency

Will Smart Factories Open the Door to Unmanned Production?

As a result of the development of technology, the decrease in human workforce in the production system may lead to less use of human resources in the production area. This in turn creates concerns about unemployment. In this case, people will need to shift to different job areas. New doors will be opened in fields such as software, system usage, cybersecurity expertise, coding science, and technology management.

The Smart Factory system is a system that obtains some consumer trends and information by using databases during production. The production of machines is done in a modern way by using various data obtained. After data analyses, necessary instructions are given to all production lines in the system and the desired product definition is made. All of these processes are carried out automatically. The problems that arise can be solved by artificial intelligence.

Currently, factories that operate with very little human labor are starting to emerge. It is possible to develop systems in the future where fully unmanned production is possible, and production may become possible without the need for humans. However, there will be a need for humans in many areas such as supervising the system, addressing software-related issues, technological coding, system analysis and interpretation, and cybersecurity.

Smart Factory will reach a level where it can produce without human involvement, but new job opportunities in other areas will be created for humans within these systems.

The Machinery Industry is a sector that constantly develops with the historical development of humanity and creates the main lines of production by bringing innovations that can be considered revolutionary. Starting from ancient times, especially with the transition of humanity to collective life, human power has gradually left its place for industrial machines. The rapid growth and development in the field of industry from the past to the present have brought about mechanization and the development of machines.

The Machinery Industry is a sector that constantly develops with the historical development of humanity and creates the main lines of production by bringing innovations that can be considered revolutionary. Starting from ancient times, especially with the transition of humanity to collective life, human power has gradually left its place for industrial machines. The rapid growth and development in the field of industry from the past to the present have brought about mechanization and the development of machines.