The press brake, which is used in many sectors, especially in the industry sector, is CNC controlled and is used for bending and shaping sheet metals. The shaping process with the press brake is performed by placing the sheet metal between the punch and die and applying pressure. With the upper tool applying pressure to the die, the desired shape in sheet metal is achieved. Bending of metal materials are carried out with the software uploaded to the machine priorly. As Durmazlar, we searched for answers to the “what is a press break?” question for you in this article.

With the press brake machine, which can adapt to developing technology, the aim is to make higher quality, faster and easier production. The level of pressure to be applied to the sheet metal can be adjusted with press brake machines and the bending process is carried out with the values set from the CNC control unit.

Before the press brake machine is put into operation, the shaping to be done is designed and the process is carried out according to the design made. The operator in charge of using the machine makes precise adjustment on the machine based on the design prepared. Making of these adjustments facilitate the bending and shaping process that the operator will carry out and eliminate the risk of error.

Press brake occupies a significant role in production. If you want to become a pioneer in your industry, these are the machines you should prefer.

How Does A Press Brake Work?

In addition, the question “what is a press brake?” a following one, that is “how does a press brake work?” follows as one of the most frequently asked questions. Press brake places the upper tool on top of the sheet metal, applies pressure and thus, bends the sheet metal. Press brakes bend the sheet metal in question to achieve the desired form and sheet metal has the ability to bend multiple times. Bending a sheet metal requires a significant amount of force. Press brakes are firm and durable equipment and are necessary for consecutive bending processes. There are different types of press brakes. There are divided into three groups such as; hydraulic, electrical, and hybrid system (a system where electrical and hydraulic are used together).

What Are The Advantages Of Press Brakes?

One of the main advantages of press brakes is that it gives you the opportunity to carry out your company’s sheet metal bending needs within your company. By this means, there will be no need to outsource your sheet metal bending needs externally.

Secondly, thanks to the ever developing technology, there are many press brakes with energy saving features. The advanced machines provide saving from electrical costs. The third advantage is that you will be able to provide saving from manpower with an automatic press brake.

Key Points of Press Brake Machines

Press brakes have been subjected to many technological changes since the first day they were manufactured. Therefore, it is not safe to make a generalization about the manufacturing machines. Those who wish to purchase new or secondhand press brakes must gain insight about the machine operation principles and the changes between the machines. There are basic details that everyone must know about press brake technologies. Otherwise, there may be situations such as not purchasing a machine with the right specifications and the desired performances may not be achieved in the processes. Having general information about these technologies provides great advantages.

While selecting the right press rake for your enterprise, you should consider the type and thickness of the sheet metal to be bend. There are different types of metals with various features. While aluminum alloys are easier to bend, durable steel requires greater force for bending. In order to sort this out, you need to identify your needs during the purchase period and make sure that the machine you have selected can be adjusted with your business requirements. Apart from this, you need to check the bending force you will need.

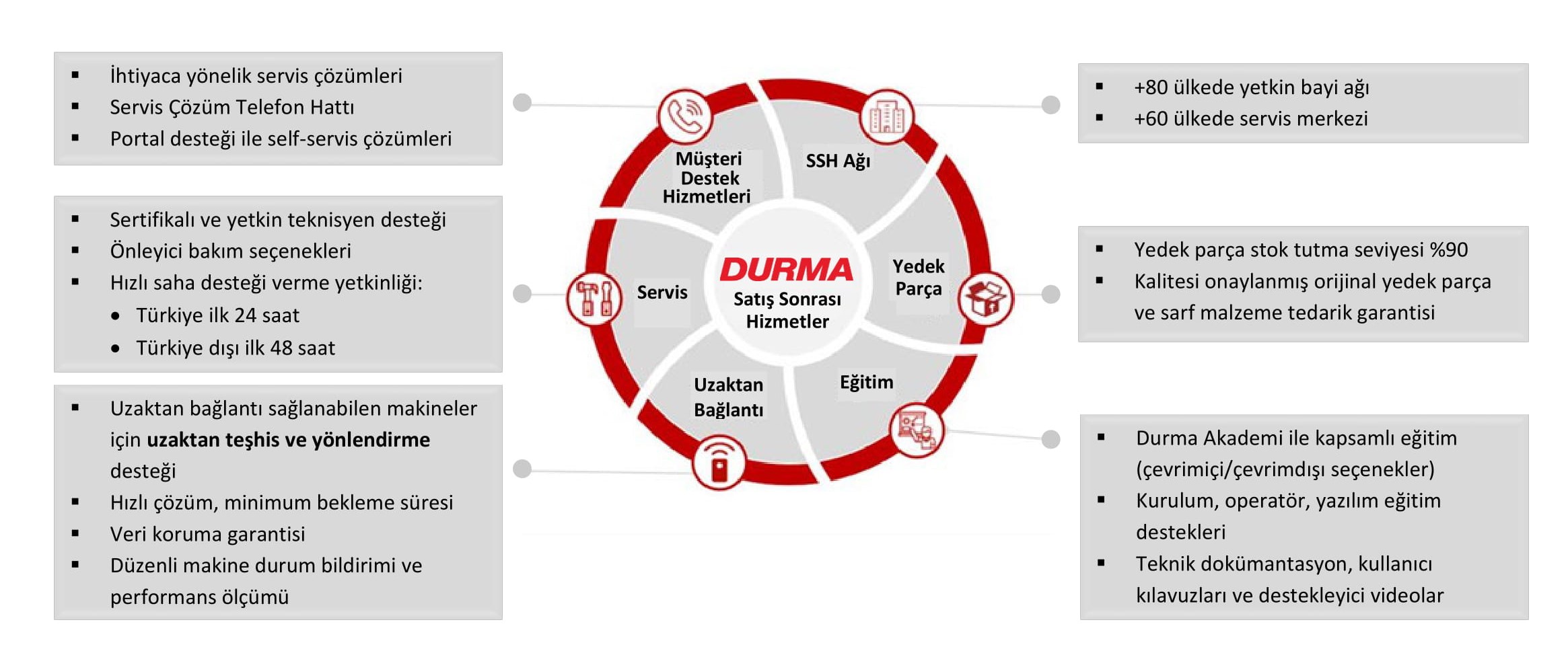

Our Office Experts access machines remotely and provide solutions to 60% of all our requests via phone or written solutions, imposing no financial burden to our valued customers.

Our Office Experts access machines remotely and provide solutions to 60% of all our requests via phone or written solutions, imposing no financial burden to our valued customers.